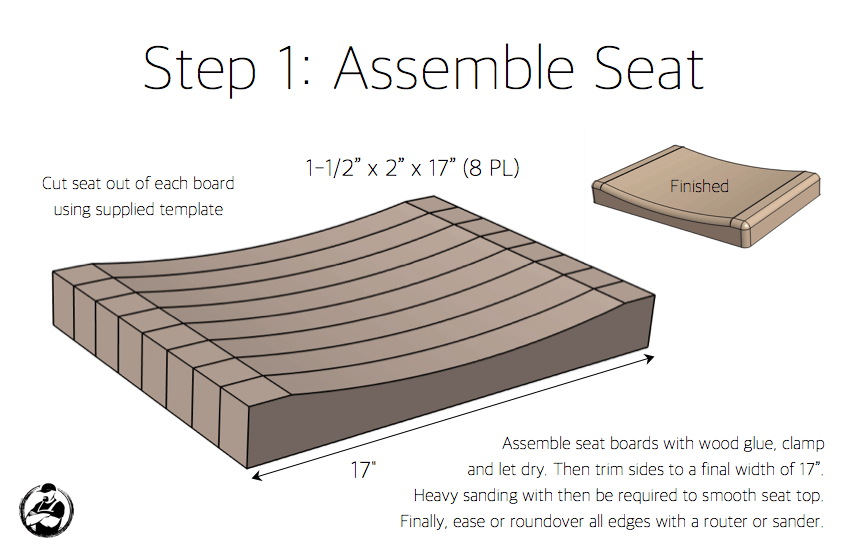

In the house that we are renovating we are planning for a small counter height area to pull up a couple of stools. I knew we needed bar stools and I knew I wanted something a little nicer than a simple bar stool. I wanted to make curved seat bar stool but I knew I didn’t have the tools required to do so. Or so I thought. Then I decided that I could just cut the curved seat out of each board before I assembled it. So that’s what I did, and I think it worked out great. And can you believe it was made out of only three 2x4s and for about $10!

For sneak peeks of our upcoming projects be sure to check out Our DIY Life on YouTube, follow us on Facebook and Instagram. Also, follow me on Pinterest to get tons of projects plans from all around the web!

Required Tools

Materials

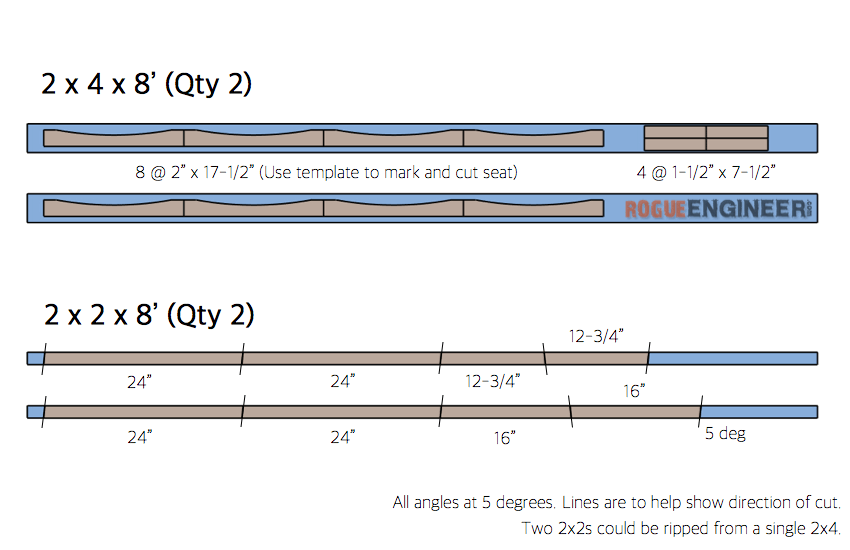

- Qty 2 – 2 x 4 x 8′

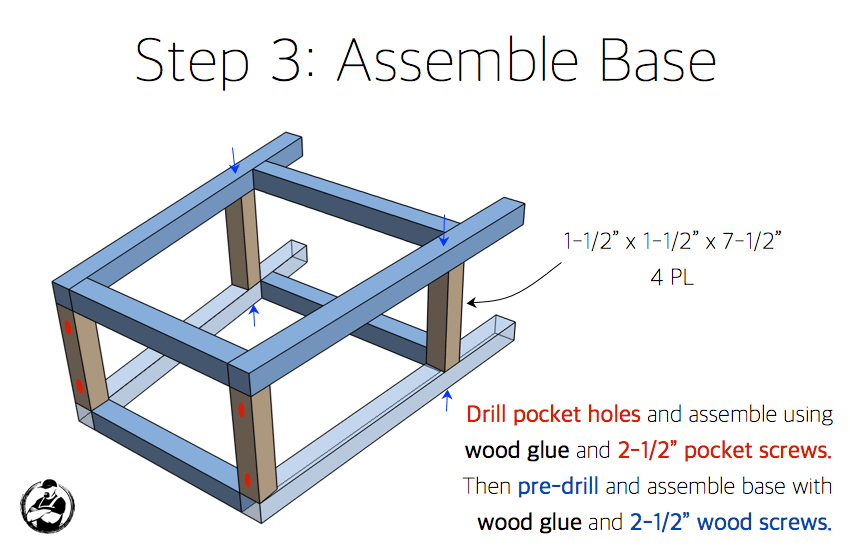

- Qty 2 – 2 x 2 x 8’

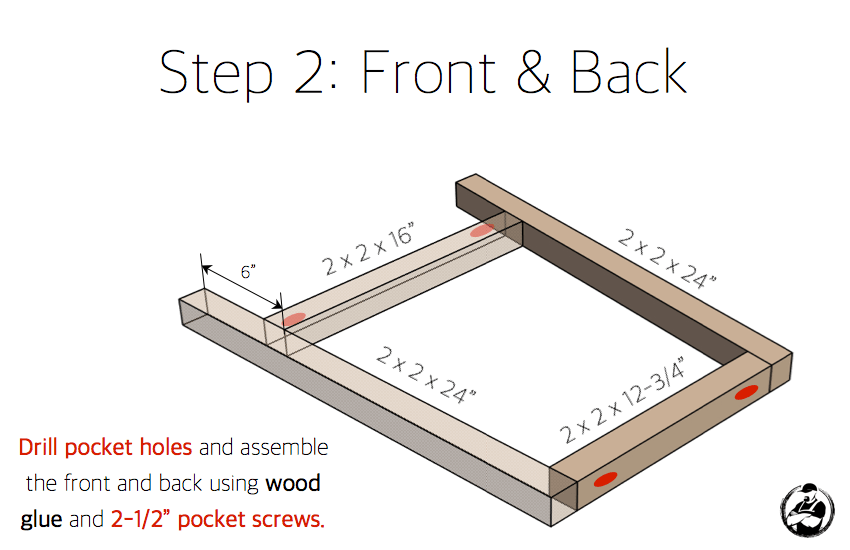

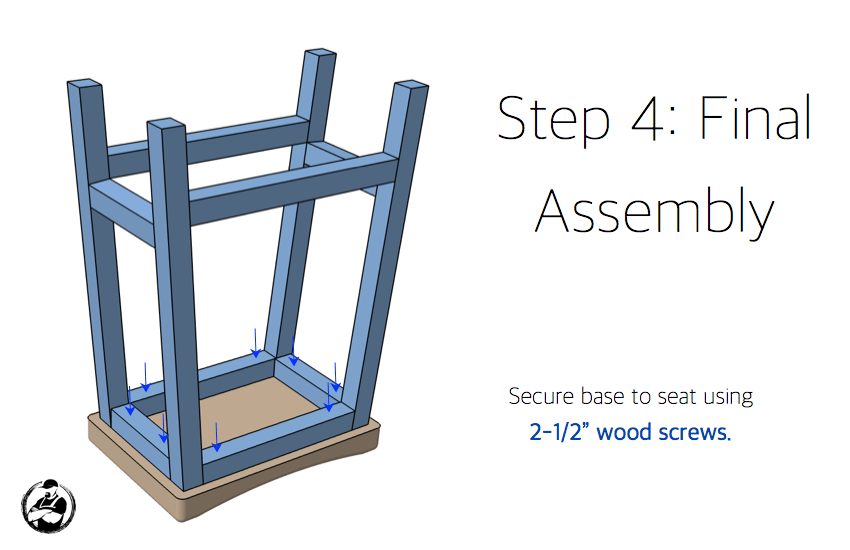

- 2-1/2” Wood Screws

- 2-1/2” Pocket Screws

- Wood Glue

Disclosure: The links provided in the “materials” and “required tools” sections are affiliate links. If you would like to support our site and help keep our content free come find out more about how we can make money with no extra cost to you.

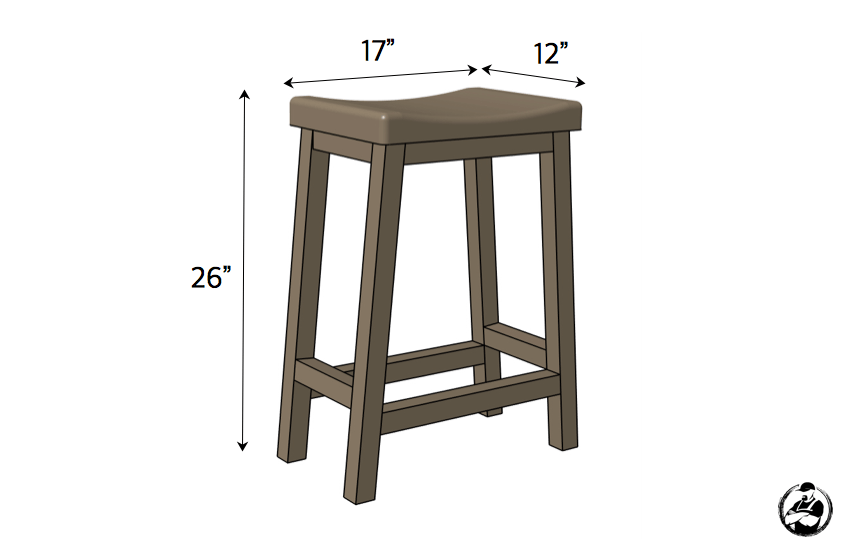

Dimensions

Cut List

How to build a Counter Height Bar Stool

If you decide to take on this project I highly recommend you download the printable PDF below to have with you during the build. To do so just click the button below and subscribe to get weekly updates. In return I’ll instantly email you the PDF for free! It’s a win-win.

Questions? Comments?

As always, if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!