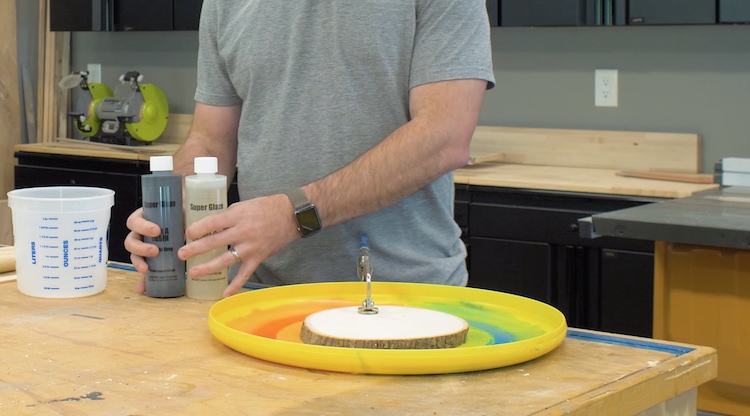

Recently, Varathane sent over their new tinted epoxy, Super Glaze, for me to try out. I wanted to combine epoxy and live edge wood because I have seen it done so many times and I think it’s a cool look. I opted to try it out on a small side table with a wood cookie in the middle. The problem was finding or building a round form that was affordable. Luckily I stumbled across this 18 inch frisbee and it made the perfect mold, plus the kids get to play with it when I’m done! I’m not super experienced with epoxy so I learned a few things along the way and hopefully I can share some of those tips with you.

If you want to see another project I used their tinted epoxy on, check out my river serving tray. Either way, I’ve got the details on both in my latest YouTube video below.

- Setup

Clean the 18″ frisbee and clamp the wood cookie to the middle so it doesn’t float when pouring the epoxy. - Mixing the Epoxy

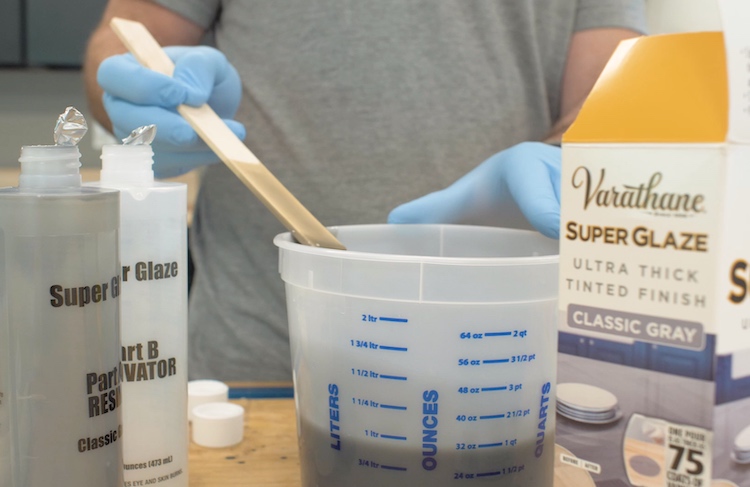

After getting the mold ready to go you can start to mix the epoxy. I used Varathane’s Super Glaze In Classic Gray and I love how easy it was to use. - The Pour

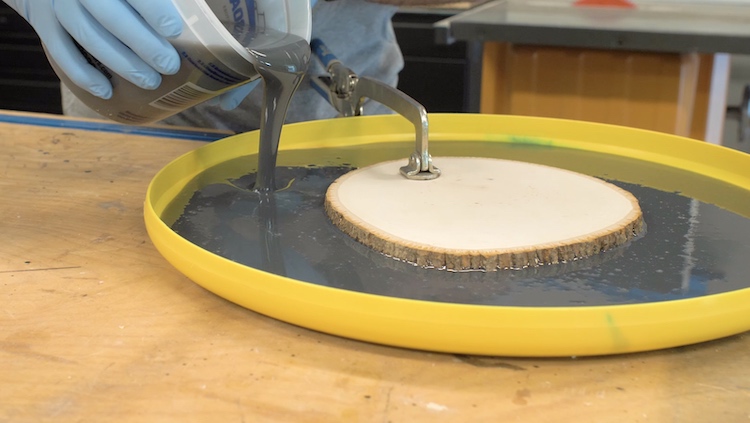

After mixing the epoxy per the instructions, use a small paint brush to paint it onto the edge of the bark. This is a step that I skipped but it will help prevent air bubbles being trapped in the bark. Then pour the remainder of the epoxy into the form. I ended up using 2 kits for this project but depending on the size of your cookie you may need more or less.

I also wanted to point out that this epoxy is a solid color. This is because of the thickness of the pour. If it was a thin coating, it would be much more transparent. - Getting the Air Bubbles Out

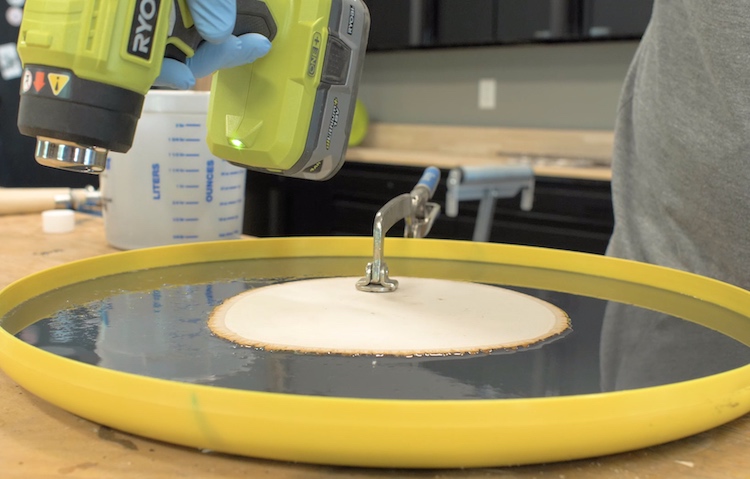

Most of the air should work itself out of the epoxy but to help it along you can use a heat gun or a blow dryer. - Sanding

I recommend a net type sandpaper like Diablo’s SandNet which won’t clog up as easily as traditional sandpaper. I sanded with 220 grit and finished with 400 grit to remove any defects as well as round over the bottom edge. - Attaching the Legs

The legs get mounted to the wood in the middle. For this I used 3 of the 15-1/2″ tapered legs with the angled top plates. The angle wasn’t quite enough to make get the stability I wanted so I increased the angle with shims. - Applying the Finish

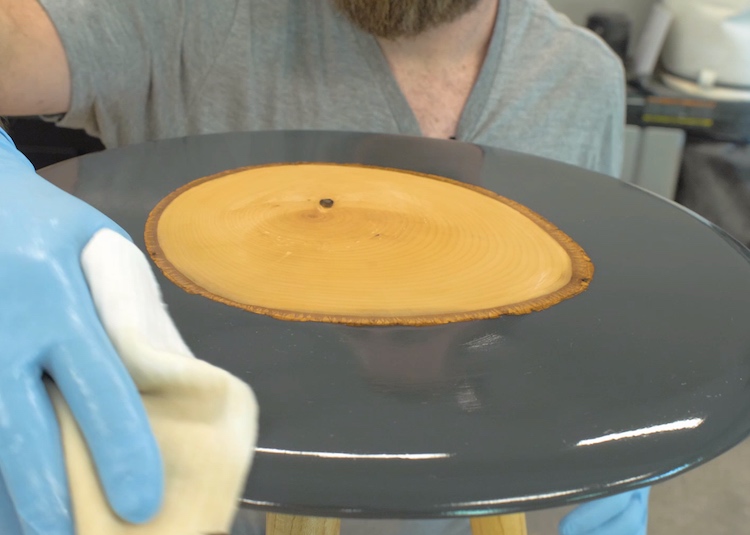

For the legs and the top I used a wipe on polyurethane finish. Applying 3 coats in total.

It’s a really easy to use product and will protect and accentuate the wood. - Buffing the Top

Finally, I used a buffer to put a final polish the top and it turned out great!

As I said before, I’m not super experienced with epoxy but I love how this project turned out! Let me know in the comments what you think or if you have any tips for others that might be attempting this project.