Some friends of ours have been wanting a DIY farmhouse table for some time now. After hearing about their shopping trip and the prices they were looking at spending on one I felt obligated to step in and make this one of my next DIY projects. My buddy Jake has no experience with power tools whatsoever, bless his heart. So, you’re in for a special treat with this one as you will get to see Jake build this table from scratch with no power tool experience! With a little guidance from me of course.

Disclosure: Some of the links provided are affiliate links. If you would like to support our site and help keep our content free come find out more about how we can make money with no extra cost to you.

Tools Required

Materials

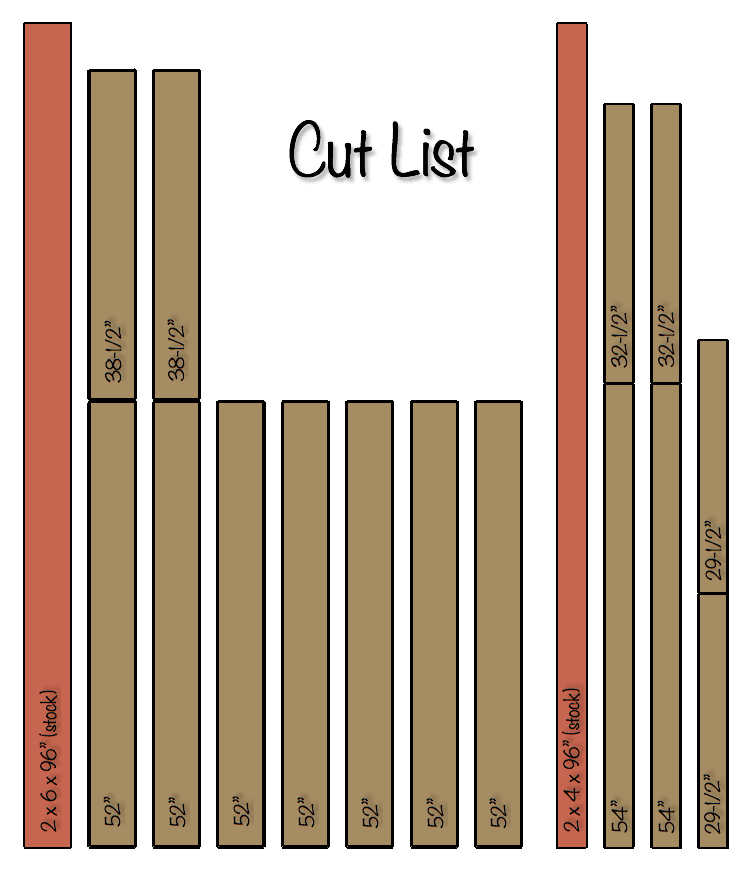

- 7x 2x6x8′

- 3x 2x4x8′

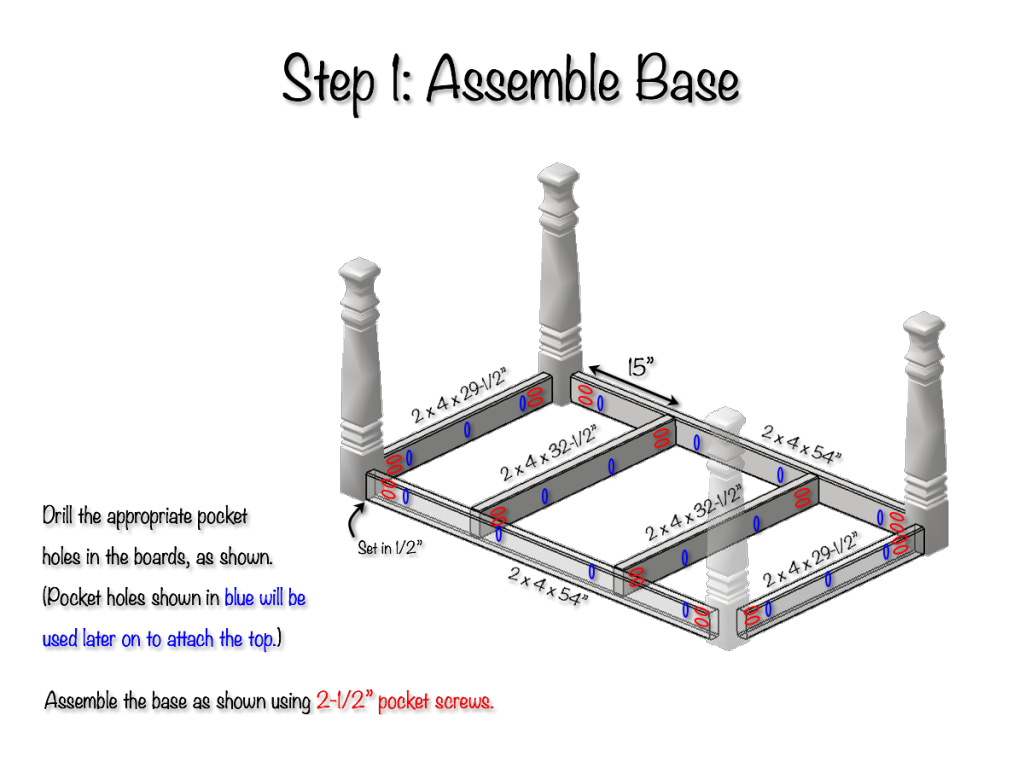

- 4x Square Husky Farm Dining Table Leg

- Purchase Amplified Plans for 15% off Code

- Amazon Affiliate Link

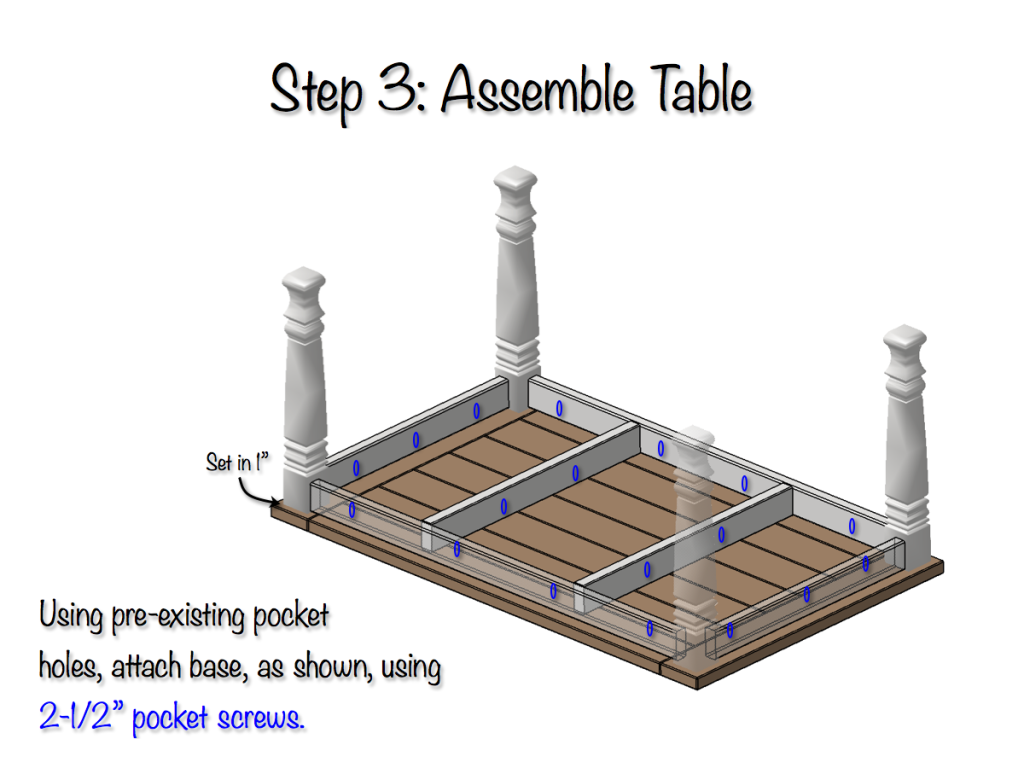

- 2-1/2″ Pocket Hole Screws

Dimensions

Farmhouse Table Plans

DIY Farmhouse Table Plans

Jake’s learning how to use a miter saw

Kreg R3 comes in hand when drilling pocket holes at the end of these long boards

Base is complete!

Stained with Rustoleum’s Carrington for the base color

Then painted and distressed with sandpaper

Jake learning how to run the foreman. This really saved us some time.

Screwed together

This is what happens when you sand and stain in the dark

fail

Rain + wet stain = fail

Maybe just fix the bad spots?

Nope! Still hate how this is turning out

Lets start all over again … 3rd times a charm.

This ol belt sander couldn’t hack it.

MUCH BETTER!

FINITO!

Finishing

Top: Rustoleum Carrington Wood Stain

Base: Distressed Finish

Base color: Varathane Carrington Wood Stain

Top color: Flat White Paint (4 coats)

Questions? Comments?

As always, if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!