We love the mix of iron and wood, but since we aren’t exactly welders… well, we had to fake it. We built this simple angled leg coffee table with faux iron rods for less than $30! This table is simple yet still adds tons of character to any room. Plus, when you make something yourself, it’s always a great conversation piece!

For sneak peeks of our upcoming projects be sure to follow me on Facebook and Instagram. Also, follow me on Pinterest to get tons of projects plans from all around the web!

Required Tools

Materials

Disclosure: The links provided in the “materials” and “required tools” sections are affiliate links. If you would like to support our site and help keep our content free come find out more about how we can make money with no extra cost to you.

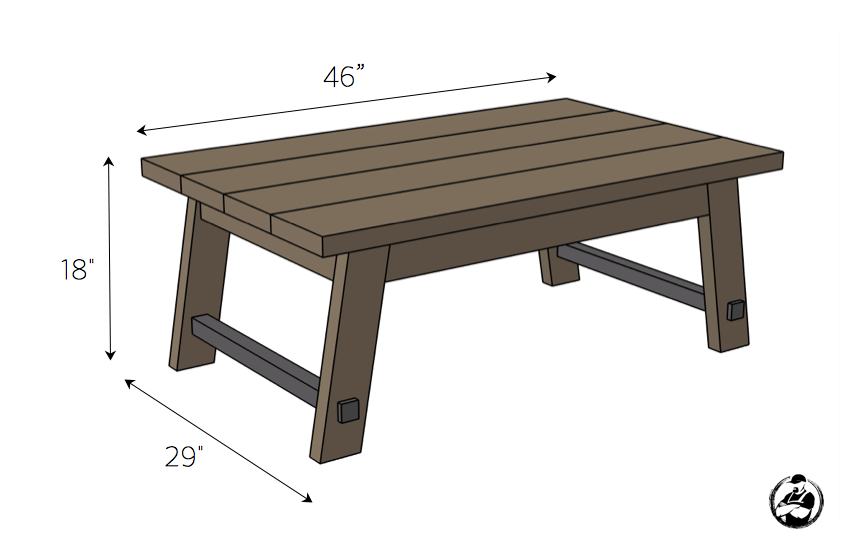

Dimensions

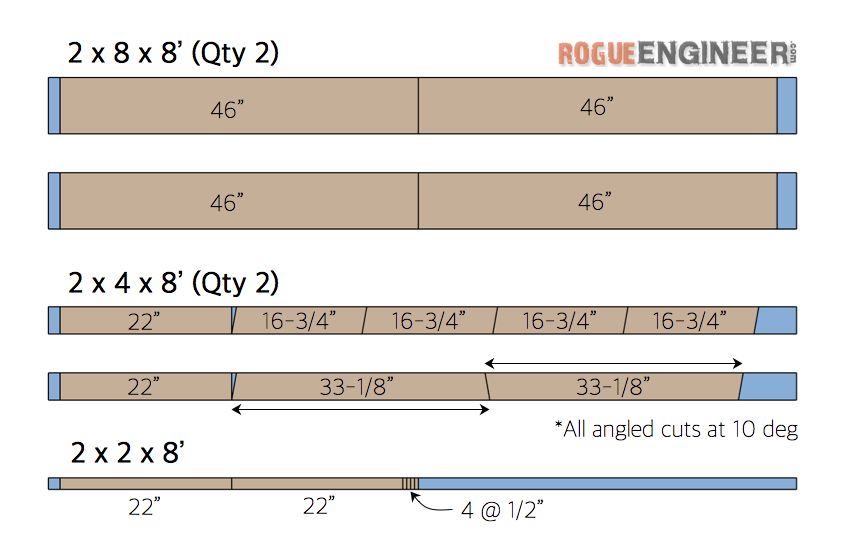

Cut List

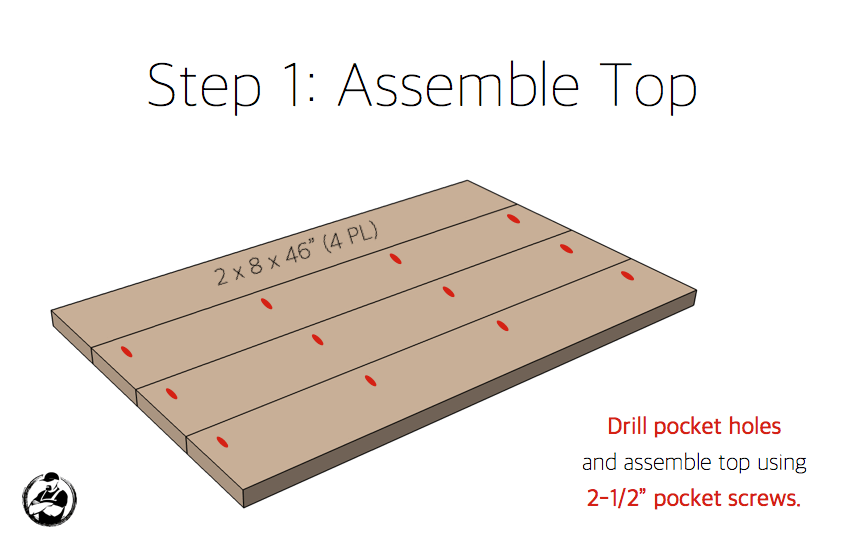

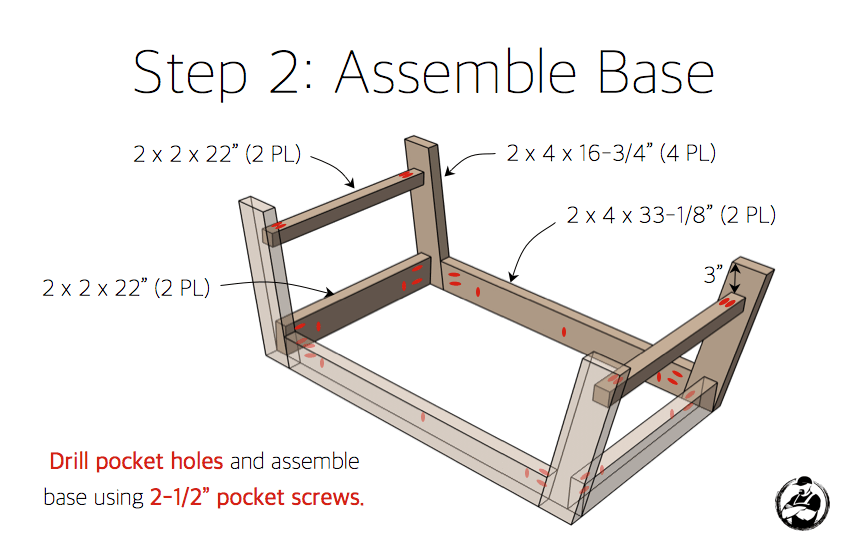

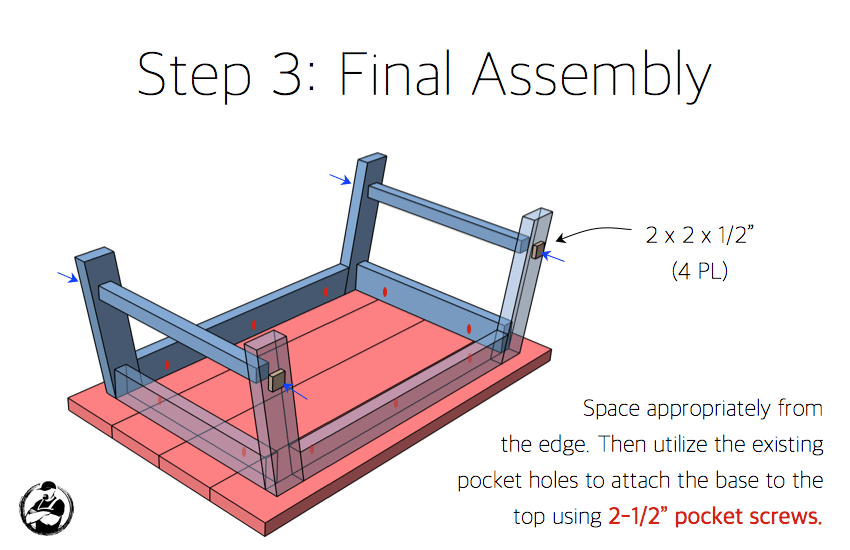

How to build an Angled Leg Coffee Table

If you decide to take on this project I highly recommend you download the printable PDF below to have with you during the build. To do so just click the button below and subscribe to get weekly updates. In return I’ll instantly email you the PDF for free! It’s a win-win.

Finishing

Since we decided to use a mix of finishes, we finished each section before we assembled the table. For the table I stained with Varathane Early American and sealed with satin triple-thick polyurethane. To see how Jamie did the “faux iron” on the 2x2s be sure to check out her faux corroded iron finish tutorial.

Questions? Comments?

As always, if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!