DIY End Table Inspiration

So after our baby Madison was born my wife asked me to haul the glider downstairs from the nursery to our master bedroom so she would have a relaxing place to nurse the baby. Right away we discovered that we needed a side table to accompany it for drinks, books, and what not. So we decided on this lovely $400 Connor Side Table from Pottery Barn. Well that’s an easy one to build. Consider it done. Here are the DIY end table plans that I created and built too myself.

Required Tools

- Miter Saw

- Kreg Pocket-Hole Jig

- Cordless Drill

- Level

- Square

- Tape Measure

- Safety Glasses

- Ear Protection

Materials

- 4x 2 x 2 x 8′

- 1x 1 x 8 x 6′

- 1-1/4″ Coarse Washer-Head Pocket Screws

- 2″ Coarse Washer-Head Pocket Screws

- 2″ Wood Screws

Cut List

- 13x 2 x 2 x 18.5″ Note: If it looks to big for you all you need to do is decrease the length of these.

- 4x 2 x 2 x 23.25″

- 3x 1 x 8 x 22.25″

DIY End Table Instructions

As always if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!

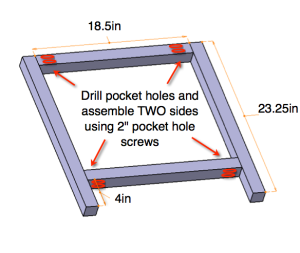

Step 1: Assembling the sides (Qty 2)

Assemble the TWO sides by drilling pocket holes at each end of the 2 x 2 x 18.5″ pieces as shown. Then, screw the 2 x 2 x 18.5″ pieces to the 2 x 2 x 23.25″ pieces as shown in the picture.

Check for square and level.

Step 2:

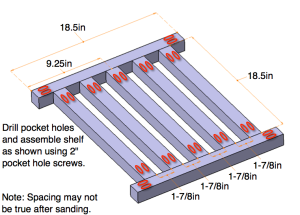

Assemble the shelf by first drilling pocket holes in each end of the seven 2 x 2 x 18.5″ pieces. It’s always best to choose wisely which side you drill pocket holes on since the opposite side will be most visable.

Using 2 inch pocket hole screws, then screw the middle slat in place making sure center is center of the ouside piece. Screw in the four remaining slats (two per side) while maintaining 1-7/8 inch gap between each slat.

Step 3:

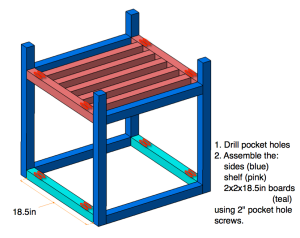

Drill pocket hole screws in each end of the remaining two 2 x 2 x 18.5″ boards, as shown in the picture.

Now assemble the table base by attaching the shelf (pink), sides (blue) and the remaining two 2 x 2 x 18.5″ boards using 2 inch pocket hole screws.

Step 4:

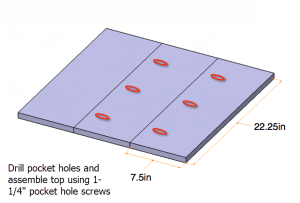

Drill three pocket holes in two of the 1 x 8 x 22.25″ boards. Make sure to adjust your jig to accommodate the 3/4″ material thickness.

To form the tabletop, assemble the three boards by screwing and gluing the joints using 1-1/4 inch pocket hole screws. Make sure to clamp the joints to assure a nice even top.

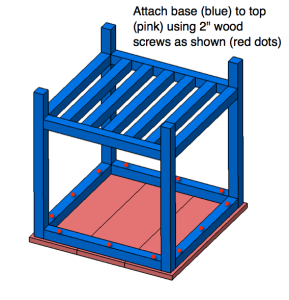

Step 5:

Attach the base to the top using 2 inch wood screws shown by red dot in this picture.

Note: If you are planning to have two different finishes for the top and base like I did then you should do so before this step.

Finish

Tabletop Color:

Base Color:

Sealant:

As always if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!