So some good friends of ours, Jeff and Cynthia, over at Whole Food. Real Families. have a little girl, Ava, who happens to be one of Brayden’s best friends. Well she had her 3rd birthday coming up and Brayden wanted to make her a very special birthday present so we decide to make her something that would last for a lifetime, a hope chest. Hope chests are popular in the south and are used by unmarried, young women, to store clothing and household items in preparation for marriage. My thought was that is could currently be used as a toy chest until then. Below I have the hope chest plans that I went by to make this.

Safety hinges on this toy chest / hope chest will keep the little ones from smashing there fingers.

A cedar shelf provides great storage for those smaller items as well as helps keep the bugs out.

Some vinyl lettering was laid over the stained area to protect from paint and after removing leaves a beautiful stained personalization.

Kids enjoying it for the first time.

Required Tools

- Miter Saw

- Pocket Hole Jig

- Brad Nailer

- Drill/Driver

- Level

- Square

- Tape Measure

- Safety Glasses

- Hearing Protection

Shopping List

- Cedar Shelf

- 1x 1 x 6 x 72″ (Cedar)

- 1x 1 x 4 x 96″ (Cedar)

- Chest

- 2x 1 x 4 x 72″ (Select Pine)

- 4x 1 x 2 x 72″ (Select Pine)

- 1x 3/4″ x 4′ x 8′ Plywood (Sandply)

- 1x 3/4″ x 2′ x 4′ Plywood (Sandply)

- 36″ Piano Hinge

- Left Side Child Safety Lid Support

- Right Side Child Safety Lid Support

- Clear Adhesive Bumpers

- 8′ 3/4″ Diameter Manilla Rope

- 1-1/4″ Pocket Hole Screws

- 1-1/4” 18g Brad Nails

- 1-1/2″ Wood Screws

- Wood Glue

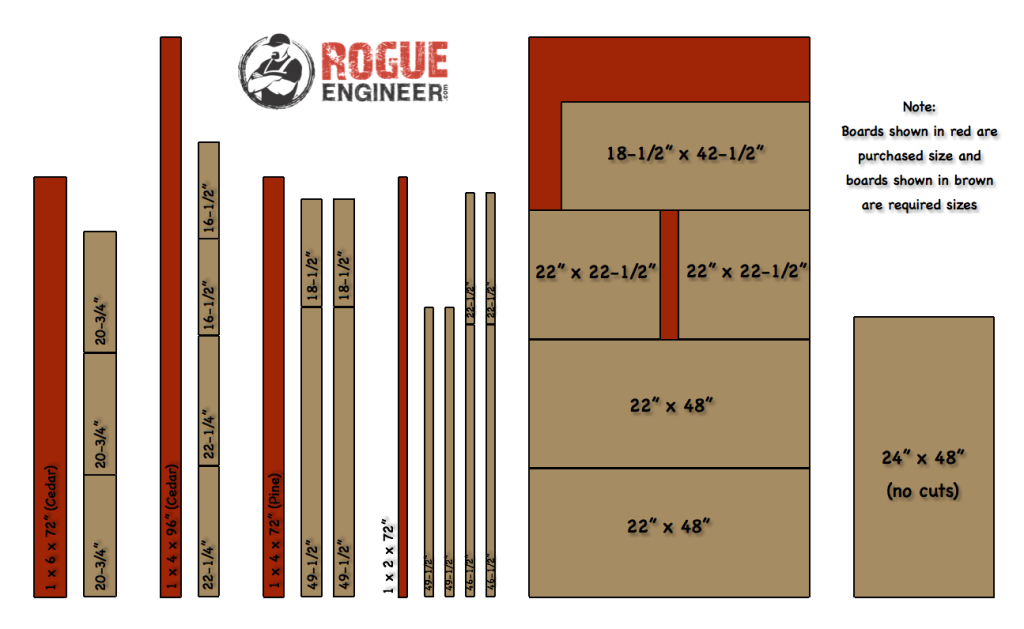

Cut List

Cut List – Print this out!

How to Build a Hope Chest

If you decide to take on this project I highly recommend you download the printable PDF below to have with you during the build. To do so just click the button below and subscribe to get weekly updates. In return I’ll instantly email you the PDF for free! It’s a win-win.

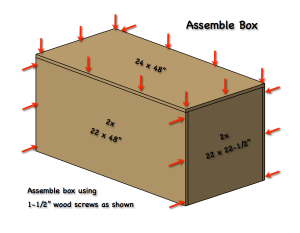

Step 1: Assemble the Box

Assemble the box as shown in the picture using 1-1/2″ wood screws. Make sure to bury the screws slightly into the wood so you can fill and sand smooth for paint.

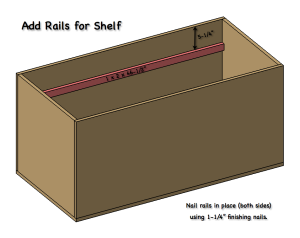

Step 2: Add Rails for Shelf

Using wood glue and 1-1/4″ finishing nails, add the two 1x2x46-1/2″ rails that the cedar shelf will sit on 5-1/4″ from the top of the of the box.

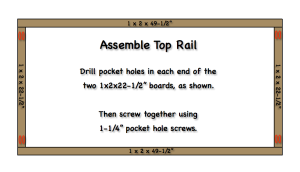

Step 3: Assemble Top Rail

Assemble top rail by first drilling two pocket holes in each end of the 1x2x22-1/2″ boards. Then screw and glue together using 1-1/4″ pocket hole screws and wood glue.

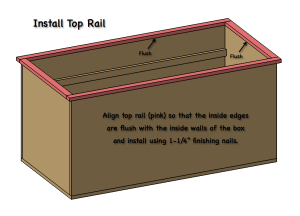

Step 4: Install Top Rail

Align top rail so that the inside edges are flush with the inside edges of the box and nail in place using 1-1/4″ finishing nails.

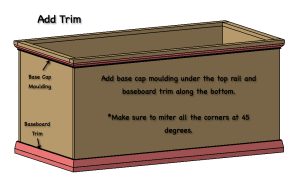

Step 5: Add Trim

Dress up the hope chest using base cap moulding around the top and baseboard trim around the bottom. Do so by cutting to size and mitering the corners at 45 degrees.

Step 6: Assemble Top

Assemble top by first drilling pocket holes in each end of the 1x4x18-1/2″ boards as well as in the 18-1/2×42-1/2″ plywood as shown. Screw together using 1-1/4″ pocket hole screws. If you’re a perfectionist like I am, you may want to

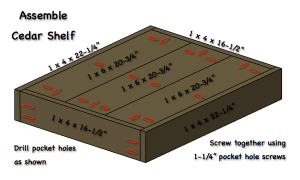

Step 7: Assemble Cedar Shelf

Assemble the cedar shelf by first drilling pocket holes in all the boards as shown. Next, using 1-1/4″ pocket hole screws, screw together the three 1x6x20-3/4″ boards to form the bottom. Now, using 1-1/4″ pocket hole screws, screw the sides together and the bottom to the sides. You may drill slots in the two side to create handles (like a serving tray) if you wish. Note: If your cedar has a rough side, face that side out so the smooth side is the only side shown when the shelf is installed.

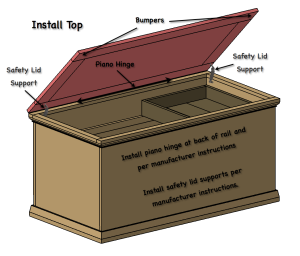

Step 8: Install Hinges, Bumpers and Top

You may want to start by painting your piano hinge an appropriate color. This is optional. You may also want to skip to finishing before completing this step.

First install the piano hinge on the back, top rail of the box and the top per manufacturers instructions. Now install right and left safety hinges per manufacturers instructions. Finally add the bumpers to the corners of the top to prevent the top from rubbing against the chest.

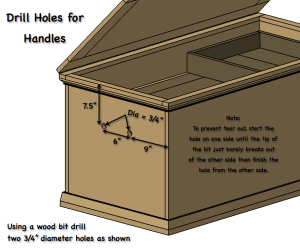

Step 9: Drill Holes for Rope Handles

Using a 3/4″ wood bit, drill two holes in the side panel of the chest. These holes should be 7-1/2″ from the top so that they do not clash with the cedar shelf. Space them 6″ apart; each being 3″ from center. To prevent tear out when drilling, make sure to start the hole from one side and as soon as the tip of the bit barely breaks out of the other side, use that as a location and finish the hole from the other side. Add handles after finishing. To do so, tie a knot as close as possible to the end. Then run the rope through the hole (from inside to out) and back in the other. Adjust to the desired length and tie knot on the inside. Pull firmly on the handle to tighten knots and cut rope as close as possible to the knots.

Some vinyl lettering was laid over the stained area to protect from paint and after removing leaves a beautiful stained personalization.

Finish

Top

We decided to stain the top with Minwax’s dark walnut stain. Then we sealed the top with several coats of clear gloss polycrylic to give it a glossy finish.

Box

For the box of this hope chest we wanted to do a distressed finish with Minwax’s dark walnut stain as the base color. We then laid vinyl lettering of Ava’s name on the front.

Get affordable vinyl lettering at wordsanywhere.com

After painting over everything with flat white paint, we then distress the edges with some sand paper and pealed away the lettering to expose the beautiful stain underneath. Then we sealed the bottom using Minwax’s finishing wax. This make for a great contrast to the glossy top.

For other finishing ideas visit the finishes page.

As always if you have any questions don’t hesitate to comment below and especially don’t forget to post pictures of your finished products in the comments! ENJOY!